3D Printed Moulds

An innovative and superior method to create highly flexible, patient-specific bolus

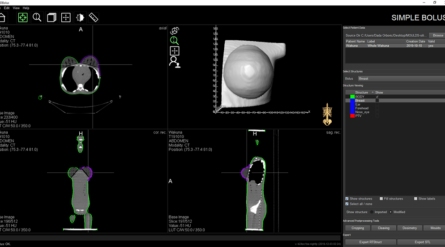

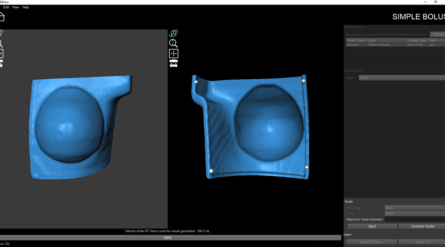

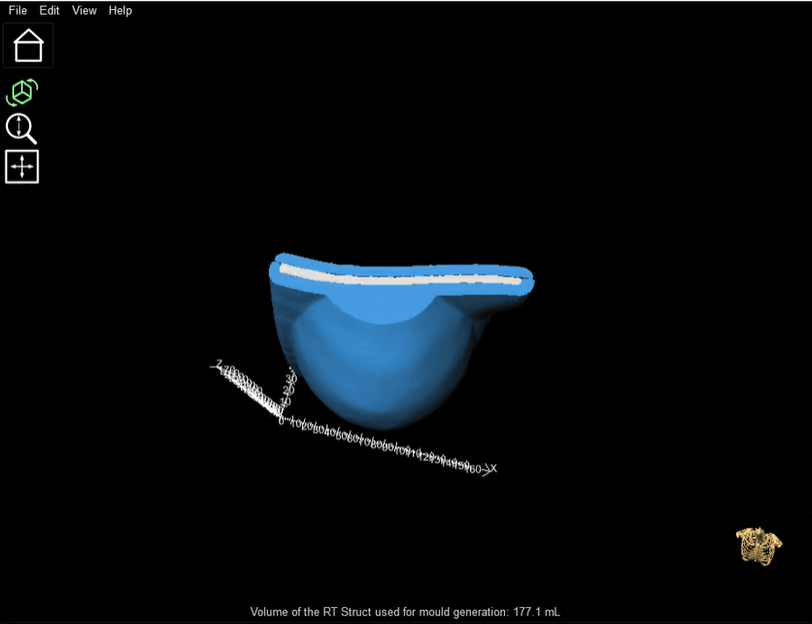

For many applications, a rigid 3D printed bolus is effective and well tolerated by the patient. However, some clinical scenarios may benefit from a soft, highly flexible patient specific bolus. We have listened to valuable customer input and created a new technology that allows users to easily create moulds that can be 3D printed and filled with flexible material to produce patient-specific bolus.

Key Benefits

-

- Allows the use of flexible materials, such as skin-safe silicone.

- Introduces a regulatory cleared process to create and produce flexible bolus with high accuracy.

- Preserves the superior patient fit provided by rigid 3D printed bolus compared to traditional methods – but offers the comfort and pliability of a soft material.

- Allows use of a bolus that copes with minor patient motion or changes between treatment fractions.

- Provides a solution particularly useful for head and neck or skin cases, or other complex anatomies requiring custom fit bolus.

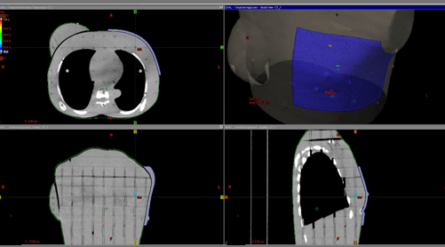

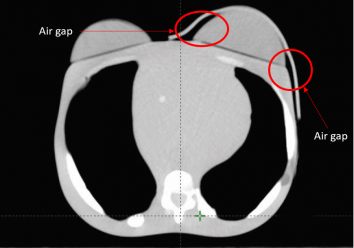

Traditional sheet bolus used on curved surfaces, such as a breast, can result in poor conformity and resultant air gaps.

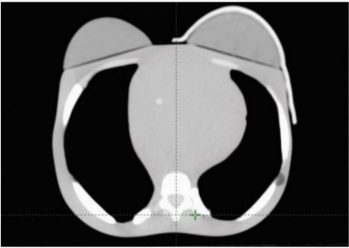

Flexible, patient-specific bolus provides superior fit and adheres to the surface shape of complex anatomies, such as a breast.

Workflow - 3D Printed Moulds

We're Here For You

Every customer is encouraged to provide insight and feedback about our software to help influence our product road map. A dedicated team of software engineers, developers, and medical physicists can take your ideas, prototype them, and quickly turn them into reality.

How We Support Our Customers

We help every customer leverage our world-class product to achieve their desired clinical outcomes so they are more successful.

Identify key customer expectations

Every customer will approve their own plan

Map out processes to meet customer expectations

Establish path to success in advance

Define metrics for each expectation

Establish realistic and measurable metrics

Quantify a goal

Establish realistic goals to help assess performance

Assign responsibility

A dedicated individual (or team) will support every customer

Establish a schedule

We will ensure you stay on track

What People Are Saying

Happy Customers

We 3D printed, then scanned the bolus on the patient. The bolus fit very well and the dosimetry was excellent, especially with regard to 90% dose conformity. All are pleased, including our Radiation Oncologist, Medical Physicist and Radiation Therapists involved. A plan like this wouldn’t be possible any other way.

Nova Scotia Health

Halifax, Nova Scotia, Canada