Simple Bolus

Enhance clinical precision, efficiency, and patient care

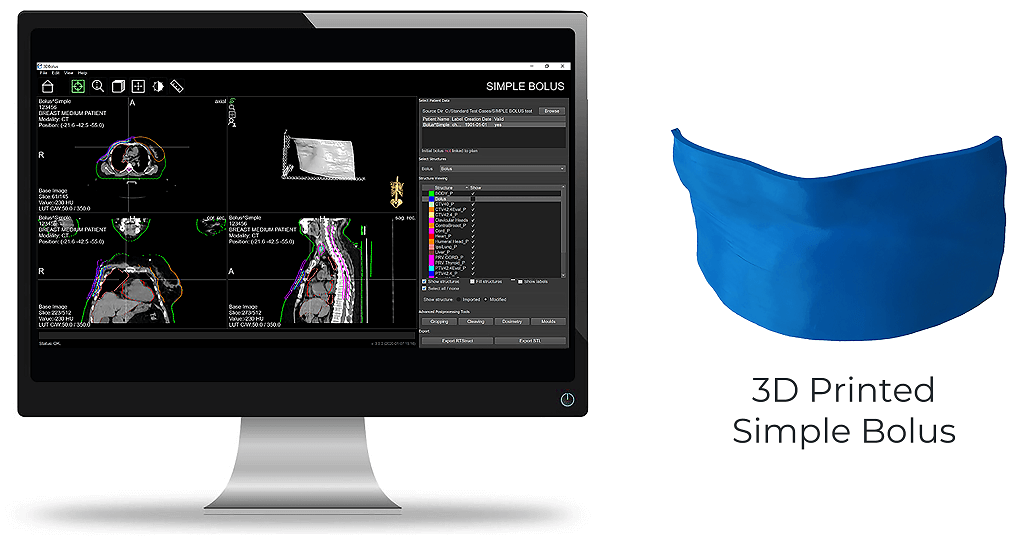

Our Simple Bolus software module allows users to confidently create patient-specific accessories that significantly reduce air gaps, spare healthy tissue, and provide superior dose distribution compared to traditional methods.

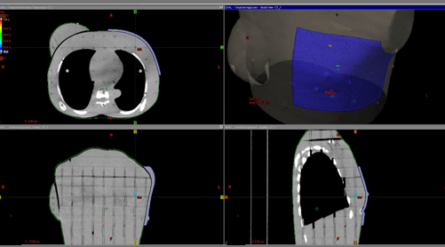

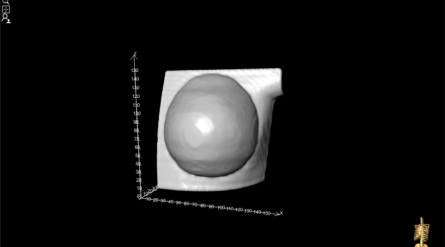

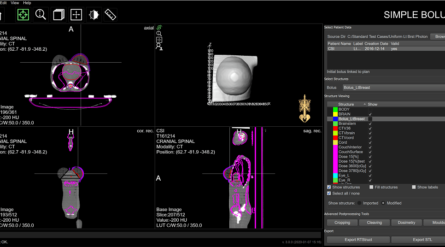

Our regulatory cleared software converts patient DICOM data into a digital model that can be 3D printed.

Key Benefits

Integration with clinical workflows enables users to create patient-specific bolus on demand using our regulatory cleared software:

- Patient-specific fit reduces air gaps and surface dose uncertainty compared to traditional sheet bolus.

- The only regulated solution that allows users to customize a bolus, export the modified structure back into their TPS, and use the TPS to calculate dose.

- Eliminate the need for multiple, 3rd party software solutions that require excessive design time and do not have regulatory clearance.

- Confidence that what is planned in the TPS will result in a printed accessory that follows strict QA requirements used in radiation therapy.

- Adaptiiv software includes numerous post-processing features to ensure optimal and accurate bolus customization:

- Smoothing: A smooth bolus surface improves patient comfort.

- Cropping: Improves printing success by creating a flat area for adhesion to the print bed.

- Patient ID: An unique patient identifier label can be printed directly onto the bolus.

- Cleaving: Cleave a bolus into two parts (at any angle) to treat complex patient anatomies, such as large extremities.

- In Vivo Dosimetry: Create and print dosimeter pockets directly within a bolus, enabling real-time recording of dose received by individual patients.

3D Printed Moulds

We now offer an innovative and superior method to create soft and flexible patient-specific bolus. By listening to customer feedback, we developed a solution that allows users to easily create moulds that can be 3D printed and filled with flexible material to produce patient-specific bolus.

Learn more about this regulatory cleared process.

Workflow

What People Are Saying

Happy Customers

An individual was already 2 weeks into their treatment plan and the clinic was struggling with the time required to fabricate the device using standard sheet bolus. Since the patient was already undergoing treatment, we wanted to make the bolus as fast as possible. Using Adaptiiv’s software solution we were able to print the entire bolus overnight, ensuring it was ready for the next day’s treatment.

Brian Overshiner

Staff Radiation Therapist

Indiana University School of Medicine

We're Here For You

Every customer is encouraged to provide insight and feedback about our software to help influence our product road map. A dedicated team of software engineers, developers, and medical physicists can take your ideas, prototype them, and quickly turn them into reality.

How We Support Our Customers

We help every customer leverage our world-class product to achieve their desired clinical outcomes so they are more successful.

Identify key customer expectations

Every customer will approve their own plan

Map out processes to meet customer expectations

Establish path to success in advance

Define metrics for each expectation

Establish realistic and measurable metrics

Quantify a goal

Establish realistic goals to help assess performance

Assign responsibility

A dedicated individual (or team) will support every customer

Establish a schedule

We will ensure you stay on track