Customer Spotlight - Sutter Health

Featuring Kelly Hosier, Medical Physicist

Adaptiiv is pleased to share an in-depth interview with Lead Medical Physicist, Kelly Hosier at Sutter Health (Sutter).

Kelly Hosier holds an undergraduate physics degree from Ursinus College and a Masters in Medical Physics from the University of Pennsylvania. She is currently an ABR certified Lead Physicist specializing in HDR and 3D printing at Sutter Medical Foundation in Sacramento, CA.

Q: How did Sutter build the internal business case to adopt the Adaptiiv solution?

A: Multiple evaluations went into developing a business case for the purchase. For the initial project intake phase, we gathered historical data on the number of patients who could have benefited from custom bolus production to get a sense of caseloads. We also compared the price of commercially available bolus material (Superflab, aquaplast, etc.) with the cost of materials for 3D printing. However, the driving force for purchasing Adaptiiv was implementing a skin HDR brachy program at our main center. The 3D printer would replace the need to purchase other surface applicator solutions for this program.

Q: What was Sutter’s experience implementing Adaptiiv software into the existing RT workflow?

A: Our department had a lot of excitement to commission a 3D printer for clinical use and a lot to learn since it was a new piece of technology for staff. Adaptiiv made the process very straightforward. Adaptiiv provided a thorough training course to familiarize our team with the intended workflow. We scheduled multiple remote sessions with the trainers focusing on different aspects of the software in each lesson. There were multiple sessions, and our team could dive into more detail for each software module and become very familiar with the design and post-processing workflow. Adaptiiv also offers a fantastic online portal with documents and videos for continuous reference and training.

Q: What type of cases is Sutter using Adaptiiv technology for?

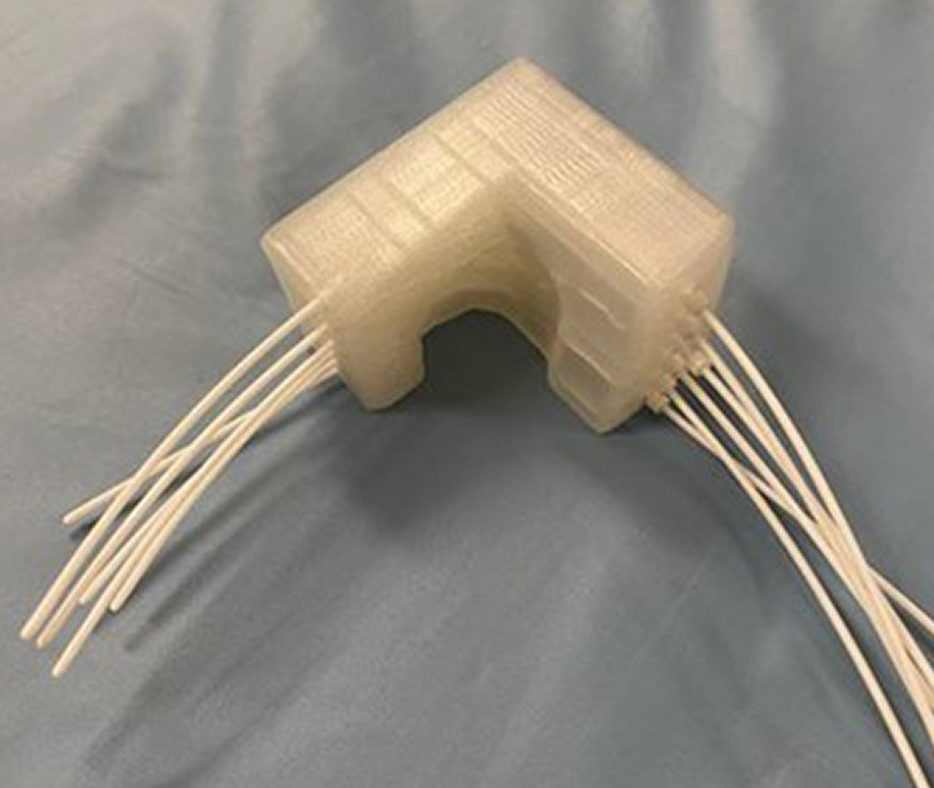

A: The Adaptiiv software and 3D printer are used for various cases from external beam to brachytherapy. We recommend using customized 3D bolus for electron therapy in treatment areas where traditional slab bolus does not conform well to patient geometry. We have treated areas such as forehead, scalp, ear, nose, cheek, chest, penis (Figure 1), and feet to date. For each case, physicians choose the material for the bolus since we have commissioned the use of both PLA and silicone rubber (for a more flexible option).

Figure 1: A 3D printed HDR brachytherapy applicator used to treat SCC of the glans penis.

Q: Have you found any alternative applications for the 3D printer in your treatment center?

A: Yes! Getting the Adaptiiv software was a great introduction to 3D printing. Once we grew more familiar with 3D printing, we brainstormed other uses for the technology, such as:

3D Printed Silicone Moulds

One of the great things about the 3D printer is the ability to print moulds (Figure 2) that can be used to create silicone rubber objects. The cost of commercially available slab bolus can be expensive (approximately $100 per 30 x 30 cm² sheet). Our center evaluated the cost of creating an in-house standard thickness bolus using a 3D printer and silicone rubber. The in-house production was estimated to reduce the cost to approximately $25-35 per bolus slab, depending on thickness. We have not yet transitioned to in-house slab bolus fabrication, but it is a project we are keeping in mind due to the cost savings.

Figure 2: A 200 x 200 x 5 mm³ 3D printed mould for in-house silicone sheet bolus production.

Thin-Walled Cylinder Spacers

For some breast cases, we have used tampon cardboard tubes as spacers in areas with skin folds to reduce dose to the skin during treatment. However, the cardboard tends to deteriorate over the course of treatment and is single use before disposal. We also encountered supply chain issues resulting in a backorder of tampons, which prompted us to think of other solutions.

Using the 3D printer, we now print thin-walled cylinder spacers for these cases (Figure 3). These cylinders are much more durable throughout treatment and can be cleaned for use on multiple patients. They are also colour-coded by diameter to ensure that the correct number and thickness used during the simulation are used during treatment.

Figure 3: 3D printed cylinder spacers in comparison to cardboard tubes.

Q: Are there any techniques that you look forward to implementing at your center in the future?

A: We have recently started working on custom skin collimation cases using the 3D printer. While custom shielding is not officially a current feature within the Adaptiiv software, we have utilized the moulds function on a shielding contour to create patient-specific shielding moulds for skin collimation (Figure 4).

We are also excited about the recent release of Adaptiiv’s intracavitary and interstitial brachytherapy modules. Our physicians are very interested in producing patient-specific applicators for HDR intracavitary and interstitial cases and look forward to commissioning a new SLA printer for this use.

Figure 4: An example of a custom skin collimation case produced using Adaptiiv’s moulds feature.

About Sutter Health

Sutter Health is headquartered in Sacramento, where they provide coordinated care to more than 3 million Californians. Their integrated network has created a connected model of care that delivers coordinated healthcare when, where, and how people need it.

The benefit of using the 3D printed bolus is the reduction of air gaps during treatment as well as designing a non-uniform bolus to shape the treatment dose. Therapists have given positive feedback on the 3D prints. The customized bolus improves patient comfort and ease of setup for treatment.

Kelly Hosier

Lead Medical Physicist

Sutter Health