Adaptiiv On Demand TrueFlex Modulated Electron Bolus (MEB) for Ear

University of Rochester Medical Center Patient Case Study

Overview/Description

Adaptiiv Medical Technologies Inc. (Adaptiiv) offers cancer centers regulatory cleared software to design and 3D print patient-specific radiotherapy accessories.

This case exemplifies how Adaptiiv’s Modulated Electron Bolus (MEB) solution enhances the clinical precision of external beam radiation therapy for squamous cell carcinoma of the left ear and external auditory canal. The custom 3D-printed bolus ensures uniform dose distribution for this challenging anatomical site, all while prioritizing patient comfort.

Patient History

A 91-year-old male with squamous cell carcinoma of the left ear presented to our clinic. Due to the tumor’s location and depth, electron beam therapy with a bolus technique was selected as the treatment approach.

Figure 1: Squamous cell carcinoma of the left ear.

Design & Fabrication

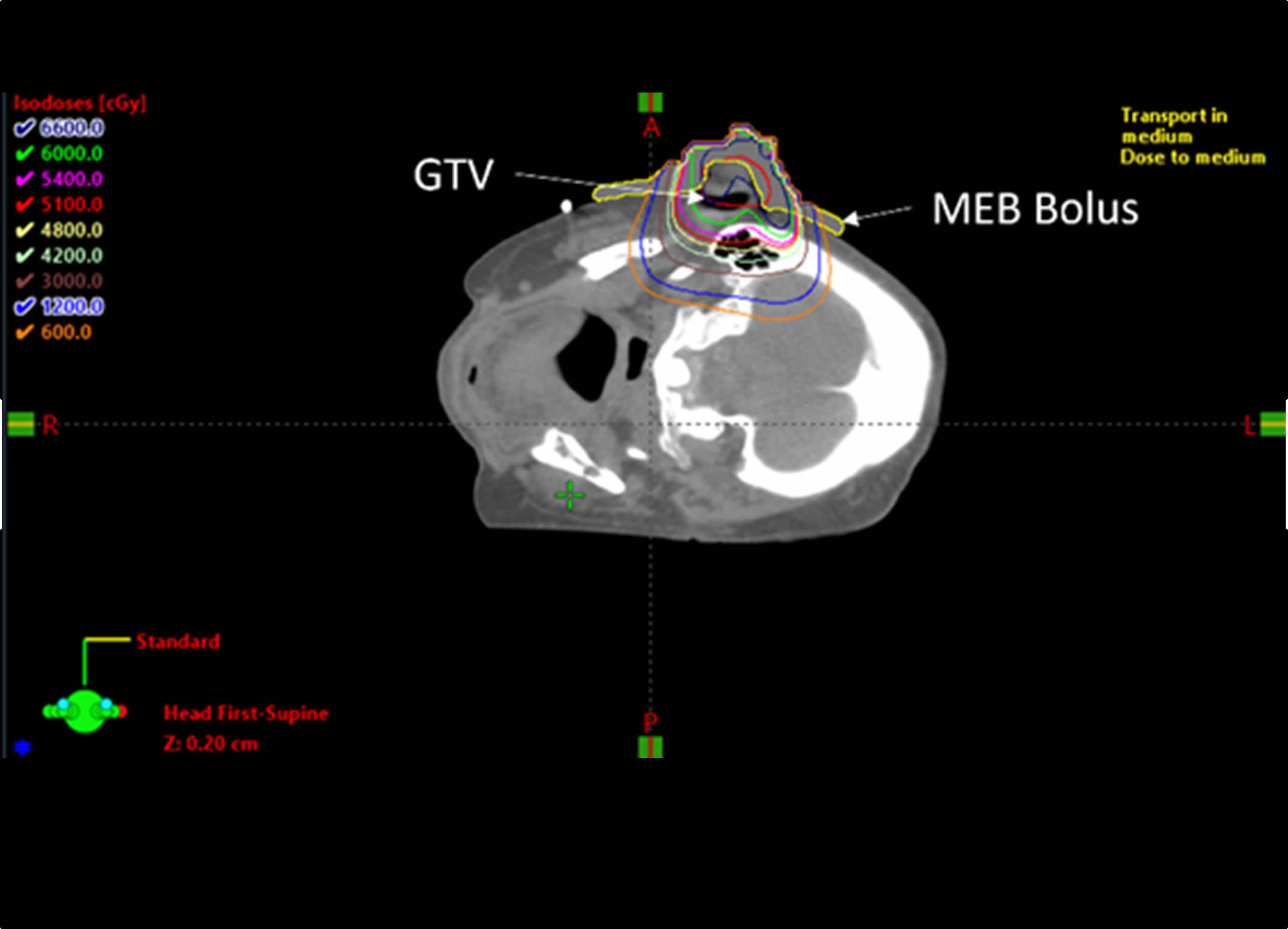

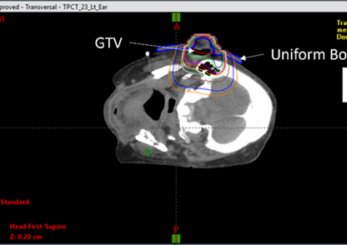

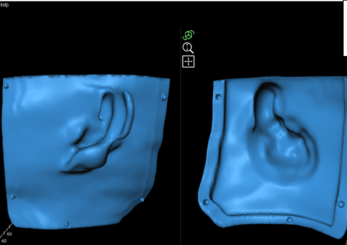

In this case, achieving a uniform dose to the ear was the primary objective for the patient. Figure 2 illustrates the patient’s initial simulation setup.

Figure 2: Showing the initial simulation setup images.

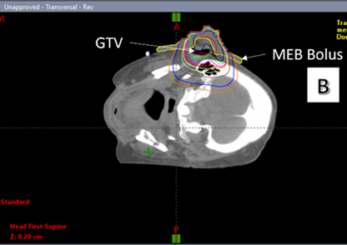

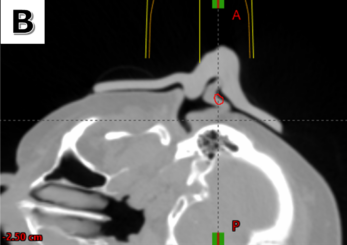

To achieve a uniform dose to the GTV, a 12 MeV electron plan with a 5 mm uniform bolus (RED=1.00) was created. The treatment planning system (TPS) was then used to normalize the dose distribution such that 85% of the prescribed dose covered the entire GTV. Subsequently, the 85% isodose line was exported along with the GTV, bolus, and CT data to Adaptiiv 3D Bolus software for MEB generation. The final dose calculation was performed after exporting the MEB back to the TPS.

Figure 3. (A): Plan with a uniform thickness bolus.

Figure 3. (B): Plan with a MEB.

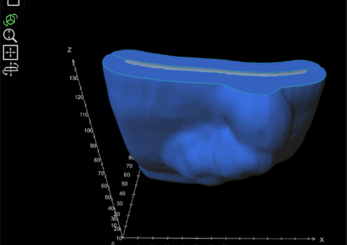

Once the treatment plan was approved, the DICOM images of the bolus were converted into a stereolithography file. The design was then submitted as a mould using the Adaptiiv On Demand (AOD) service.

The mould design was automatically sent to Adaptiiv’s manufacturer, HP, leveraging the Multi Jet Fusion technology to 3D print the mould using rigid PA12 material. The mould was filled with EcoFlex 00-30 silicone to produce the TrueFlex bolus. Silicone bolus is known for its soft touch and high flexibility, making it ideal for patient comfort while ensuring conformality to a large surface coverage.

Figure 4. (A): The TrueFlex two-piece mould shown in blue, and the bolus material shown in translucent grey.

Figure 4. (B): the separated pieces of the mould showing the alignment guides to ensure the two pieces are put together accurately.

After the custom bolus was received the patient was scanned with the Adaptiiv bolus in place.

Figure 5. (A): Final planning CT setup with custom bolus.

Figure 5. (B): CT scan with custom bolus.

Dose Calculation & Verification

This newly acquired CT image set was used for the final plan creation. The bolus was included in the body contour. The patient received 70 Gy over 28 fractions, with a prescribed treatment percentage of 85%.

Results & Findings

To guarantee the quality of the TrueFlex bolus, the AOD service performed quality assurance checks, ensuring that the physical density and density of the bolus were well within the specified tolerances.

The patient tolerated the treatment exceptionally well. Daily setup was efficient due to the excellent reproducibility and conformability of the bolus. The minimal air gap and close adaptation to the patient’s anatomy significantly reduced setup time compared to traditional wax or sheet boluses.

Figure 6: Two months out from finishing treatment.

Summary

- Modulated Electron Bolus (MEB) provided precise control over bolus thickness. This customization allowed the prescription isodose line to closely match the contours of the GTV, ensuring a more targeted dose distribution.

- Adaptiiv’s TrueFlex Bolus offered a soft and flexible solution, ensuring a snug fit on the patient’s anatomy while minimizing air gaps.

- The silicone material of the bolus facilitated consistent and reproducible placement during daily treatments. This enhanced the overall patient experience and comfort.